Export of the first melt blown cloth production line in China

The first domestic melt blown cloth production line exported to foreign countries will soon be sent to India 🇮🇳 … You're over. We're just beginning!

When the machine rings, gold will be ten thousand Liang; when the machine stops, gold will be silver.

The melt blown cloth factory is racing day and night with time, with epidemic situation, with peers, trying to turn the machine, they can get the first chance in this battle.

——My die is often blocked. What should I do?

——My cloth is not even, which affects the filtering effect!

Recently, looking for a plastic point of view received a number of melt blown cloth factory consultation, in fact, in the previous article, "melt blown mixer 18 questions: soil cannon can also make N95!"! What about brittle melt blown cloth and poor filtration? 》There is already a brief description. Let's discuss it today.

1. The material has large ash and impurities

If you buy poor quality melt spray material, there are black spots (carbonization), impurities, large ash content, which is easy to block the spinneret hole, and the uniformity of cloth surface is also poor, which will also cause wire breakage, thus increasing the frequency of disassembling the die head (also called spinneret), you need to spend more time to clean the die head.

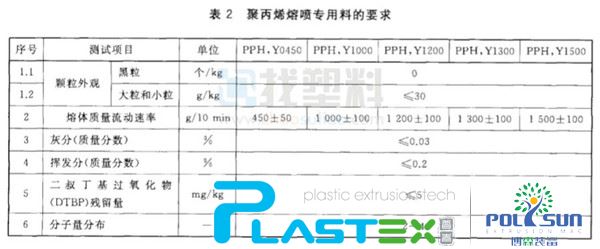

How to calculate the qualified ash content? According to the national standard GB / t30923-2014, the ash content is ≤ 0.03%. On this basis, the smaller the ash content, the better.

Then what is the ash content of the net red melt spraying material in the market? Look for the plastic viewpoint to see the data:

The ash content of mj1h15 of Sinopec is 0.01%

The ash content of Shandong dao'en z-1500l is 0.012%

The ash content of Kingfa technology pp-91500 nc001 is less than 0.01%

It can be seen that although the national standard specifies that the ash content index ≤ 0.03%, it is qualified, and the mesh red melt spray materials all pursue excellence.

Here, we recommend a melt blown material pp1500 with ash content of 0.01%. In addition, this pp1500 uses 300 mesh filter screen to filter impurities (100-200 mesh filter screen is widely used in the market). The customer has never fed back the plug.

2. Spinneret hole, not smooth enough

It is very difficult to produce spinneret nozzle, the core of melt blown cloth production equipment. For a long time, the main suppliers of high-end spinneret are in Japan and Germany. However, in recent years, China's micro hole processing technology has made considerable progress. It is understood that the spinneret of Changzhou Fangxing Precision Machinery Co., Ltd. should occupy 70% of the market share in China. Sinopec melt blown cloth production line adopts Changzhou Fangxing spinneret.

The production and processing of the spinneret hole is related to the production efficiency and quality of the melt blown cloth, and then affects the protective performance of the mask. More than 300-2000 micropores are distributed on the spinneret according to the different application levels of the melt blown cloth.

N95 mask melt spray cloth: Φ 0.15mm-0.2mm, depth 2-3mm;

N90 mask melt spray cloth: Φ 0.2mm-0.25mm, depth 2.8-3.2mm;

N80 mask fusible spray cloth: Φ 0.3mm-0.35mm, depth 3.0-3.5mm;

Some customers asked, Mingming has been using the same melt spray material, the parameters have not changed, why is the spinneret used for a long time or easy to block? Because the spinneret hole will have burr when it is used for a long time, and it is not smooth enough, it needs to be cleaned and polished regularly to remove the burr in the spinneret hole and increase the inner wall finish, so as to avoid the problems of hole plugging, sand hole and crystallization.

3. PP raw material is unstable

According to the plastic viewpoint, many melt blown cloth factories may produce high-level melt blown cloth at the beginning, but because the supply is not stable, or the quality of melt blown material is not stable, even if the machine parameters are not changed, a batch of melt blown material will not be sprayed with the same level of melt blown cloth.

Therefore, it is very important to choose a material supplier with sufficient supply and stable quality.

In addition, the level and personal preference of the shunting master will also affect the selection of raw materials, especially when exploring and debugging at the beginning, the cloth factory will often test materials continuously, and finally choose a supplier with the highest cost performance.

It is said that the trade rule of Fujian is that the shunting master asked to bring his own materials to the door for debugging. On the one hand, he earned the remuneration for the shunting machine and the profit of selling materials. It's really killing two birds with one stone.

4. No filter

Just add it.

5. The bucket is not cleaned

Well, what can I say.

6. Excessive addition of electret Masterbatch

Today, a customer from Quanzhou fed back to the plastic viewpoint. He found a master from outside to transfer the machine. The master may not have much experience. In order to produce 95 grades, he added 10% electret masterbatch! I don't know which book he learned his knowledge from. I dare to use electret masterbatch to produce N95.

This customer complains: "the master of this half bucket of water really kills people! I've delayed a lot of time. I wish I could give him a good beating. "

7. What if it's blocked?

a. Vacuum calcination:

Generally, the melting point of polymers is below 300, so when the temperature is high, the polymers melt. If the temperature rises further, the polymer will decompose. If the vacuum pump is started again, the decomposed gas can be sucked away, and the decomposed residue can be washed away by the spray water.The disadvantage of vacuum calcination is that it takes a long time, and the treatment is not clean when the pore carbon is heavy.

b. Ultrasonic cleaning method:

The ultrasonic wave acts in the liquid, which makes the liquid move and produce a large number of tiny bubbles. When the sound pressure reaches a certain value, the bubbles increase rapidly, and then suddenly close. When the bubble is closed, shock wave will be generated, and thousands of atmospheric pressure will be generated around the bubble, which will destroy the insoluble dirt and make them disperse in the cleaning solution.

At present, ultrasonic cleaning method is commonly used, but it needs special solvent, and the leakage of ultrasonic will cause certain physical injury.

c. Dry ice cleaning method:

The dry ice cleaning method takes compressed air as the power and carrier, takes the dry ice particles as the accelerated particles, sprays them to the cleaned object surface through the special jet cleaning machine, uses the momentum change (Δ MV), sublimation, melting and other energy conversion of the solid dry ice particles with high-speed movement, so as to quickly freeze the dirt, oil dirt, residual impurities on the cleaned object surface, so as to condense Embrittlement, peeling, and at the same time with the air flow clear.

The biggest advantage of dry ice cleaning method is high efficiency. Other methods take more than ten hours, and dry ice cleaning method can clean in 2-3 hours. Moreover, it is easy to operate and can be operated on site.

Of course, when the coking is very serious, we need to use a variety of methods to cooperate, even with the use of hammer, silver needle and other small tools, you can clean up according to the specific situation!

d. Abrasive flow polishing of inner hole

Abrasive flow polishing is a new technology developed in surface machining. Deburring, polishing, chamfering and recasting layer removal are achieved by extruding semi-solid fluid abrasive to the surface to be machined.

The advantage of abrasive flow process is that it has excellent performance, high efficiency and good effect in polishing inner hole and irregular shape workpiece. Spinneret belongs to precision metal hole and deep hole, which is suitable for abrasive flow polishing technology.

The disadvantage of abrasive flow process is that it is not suitable to process large size workpieces, plane polishing and outer wall of round pipes.

contact us